Peter Holderith over at The Drive recently chronicled his DIY go-cart journey of designing, sourcing, and building his very own go-cart in his small apartment (I encourage you to read his two part tale here and here). While the main fun of the article is seeing the final product and the ingenuity of its design, along with its compromises, there’s also a hidden tale about modern car manufacturers that deserves its own spotlight. Essentially, everything Peter accomplished in creating his go-cart was a miniature model of how modern car manufacturers are operated (and founded). Further than that, it explains why companies like Tesla and Rivian can pop up in a matter of years to compete against decades old (sometimes centuries) giants such as Daimler, Ford, and Toyota. It wouldn’t even be too far to say that anyone can create their own car company, in their apartment or otherwise.

The Genesis of Peter Holderith’s DIY Go-Cart

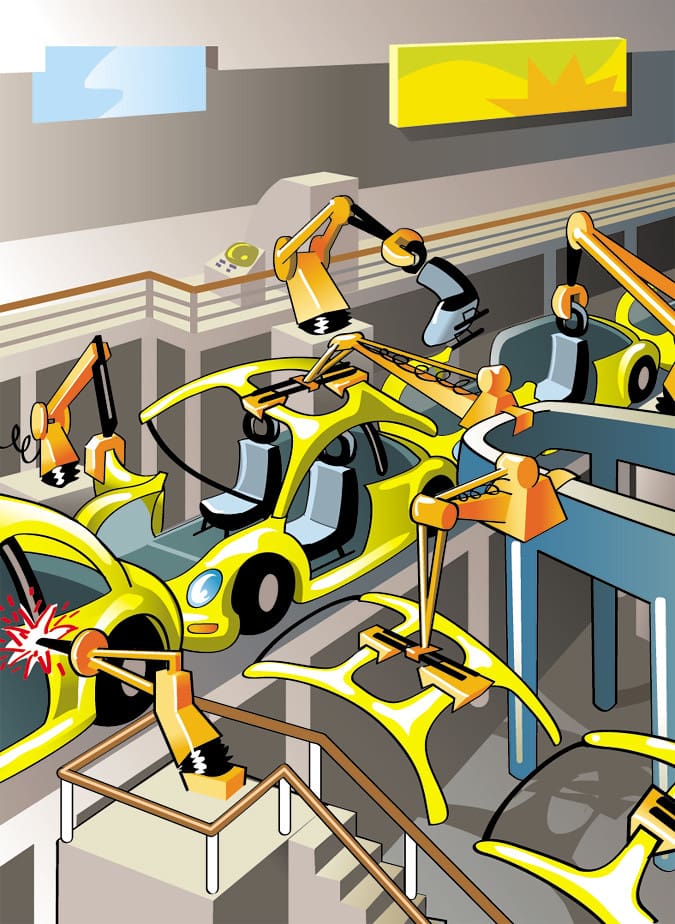

There’s a big misconception among the public about how their car actually came about. Most people go to the dealership, the dealership says Ford, the car says Ford, and if they break something the replacement parts say Ford. It wouldn’t be unreasonable to assume that Ford built the car in its entirety, but that’s not necessarily true. A large amount of people I talk to are surprised to learn that the manufacturers don’t make more than 90% of the parts that go into their car. In fact, the parts are made by tens, if not hundreds, of individual companies that are contracted out by the main manufacturer. Sometimes the parts aren’t even designed by the car company, and even more surprising, a single parts company might make parts for multiple different car manufacturers! In other words, the Hyundai you drive might have parts made in the exact same factory that made a very similar (if not the same) part that goes into a Volkswagen or Nissan.

Comparing DIY and Industry Giants

It wasn’t always like this. Historically, the major car manufacturers used to make almost all their own parts. This is referred to as vertical integration in the manufacturing industry. What happened was that, in the early years of manufacturing, it was believed that the best way to maximize profits was to make as much of your product as possible. The idea being, for each part a manufacturer didn’t make themselves someone else would instead sell that same part to them at a higher cost. Companies like Ford would take this even further. Instead of just making the nuts and bolts for their cars, they would even make the steel for the nuts and bolts, own the ships that brought ore to the steel mills, and even buy the mines that produced the ore themselves.

Eventually, anti-trust regulation would take its toll of the largest of vertical manufacturers, but the idea lasted a little longer still. What does this all have to do with a man designing a go-cart? We’re getting there.

After a while, the profit margin saved from vertical manufacturing would diminish for a number of reasons. One of the main factors was the introduction of global supply chains that allowed for cheaper labor and product to be found elsewhere than the unionized industries that surrounded the main car plants. The main killer though was bloat and competition. It was nearly impossible to run a company car company effectively when you also had to be a master at running a shipping company, a steel company, a mine, countless parts companies, or even a city, such as Fordlandia. There was so much bureaucracy, and difficulty to create communication and cooperation between the different branches, that the end product began suffering and savings diminished. Eventually, manufacturers learned that they could get better service and cut costs by putting services up for bid, having external companies compete to gain contracts. This was the dawn of horizontal manufacturing, in which companies stick to a set of core competencies (design, assembly, and marketing) while leaving the rest of the dirty work to outside contractors.

Future of Manufacturing: Lessons from the DIY World

And so, we return to Peter and his DIY go-cart. What Peter did was essentially become a horizontal manufacturer. He created the design and made specifications that he needed for his suppliers to follow (which he sourced himself), then went about setting up the best way to assemble all the bits. Finally, he tested and quality controlled his DIY go-cart before marketing it to the broader public. All Peter had to do was have an idea of what he wanted to build and then find a number of different companies who were more than willing to sell him the parts needed to create his dream (all for under $1,000 I might add). There’s a little more legal and regulation requirements involved, but that’s really all it takes to create a car company these days. So, take heart! If your dream is to become the next Tesla, it’s a lot easier than you thought it was. Hell, you can even start in your apartment.